Leading JIC Fitting Manufacturer in China

Purchase JIC Fittings in Bulk at Factory Prices

Well-known Hydraulic Fitting Manufacturer in China

Our JIC Adapter Product Catalog

JIC Adapters Overview

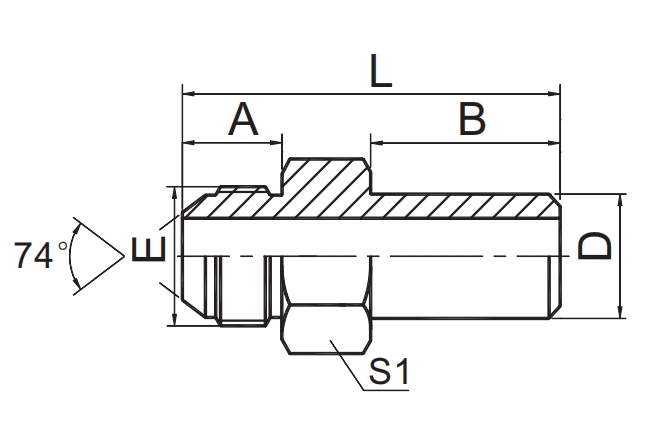

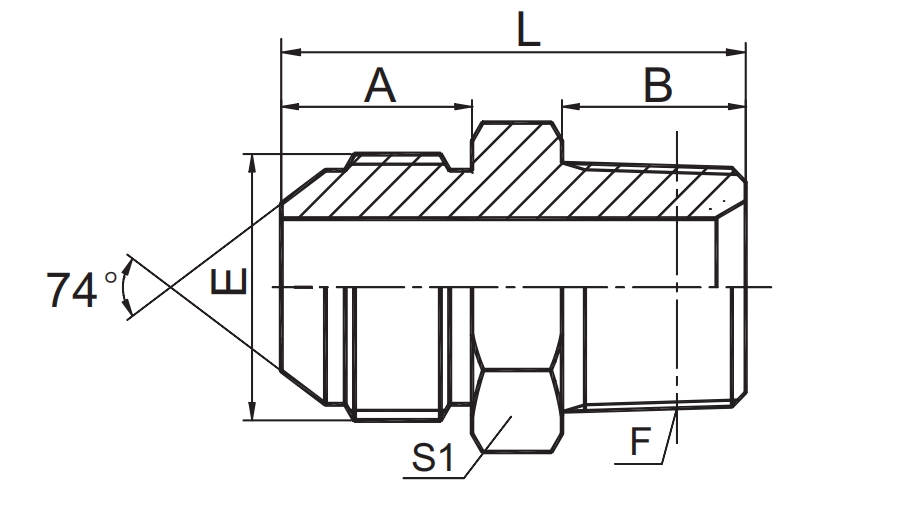

JIC adapters are hydraulic fittings built to the Joint Industry Council (JIC) 37° flare standard (SAE J514). They are widely used in fluid power systems to connect hoses, tubes, and components securely while ensuring a leak-free seal under high pressure.

The 37° flare design provides excellent vibration resistance and allows repeated assembly without damaging the sealing surface. JIC adapters are compatible with a wide range of hydraulic fluids and are a preferred choice in industries such as construction, agriculture, manufacturing, marine, aerospace, and oil & gas.

Key Features of JIC Adapters

- 37° Flare Sealing Surface – Creates a reliable, reusable metal-to-metal seal that resists leaks.

- SAE J514 Standard Compliance – Ensures dimensional accuracy and interchangeability with other JIC fittings.

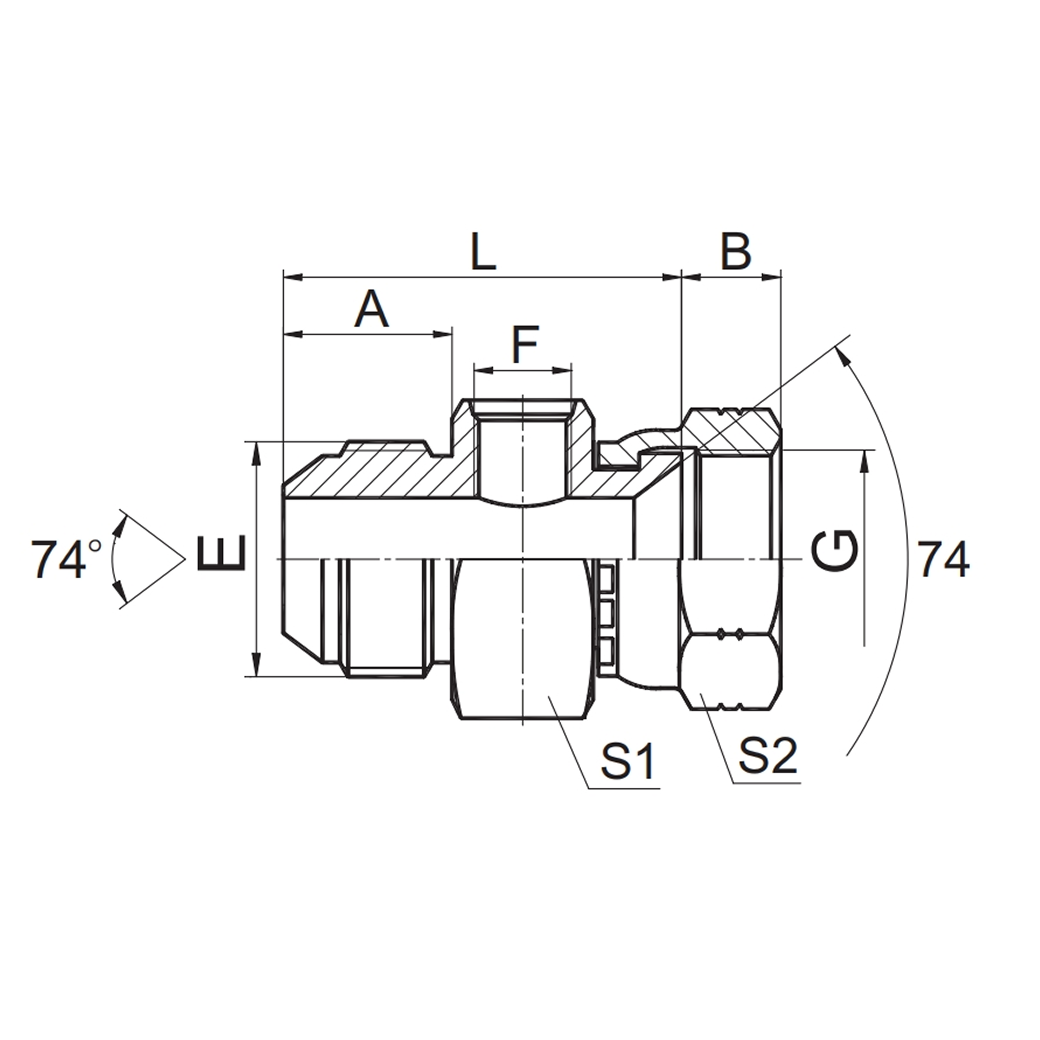

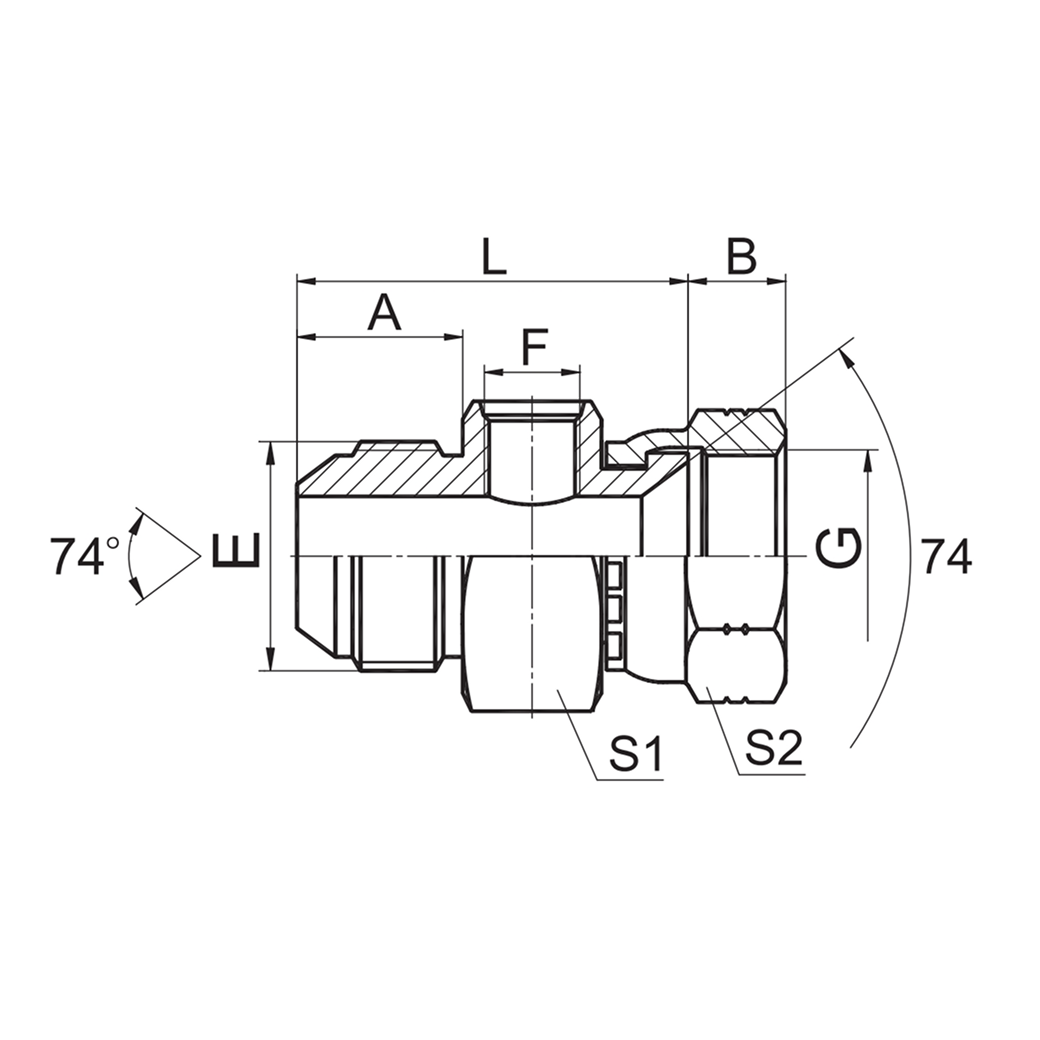

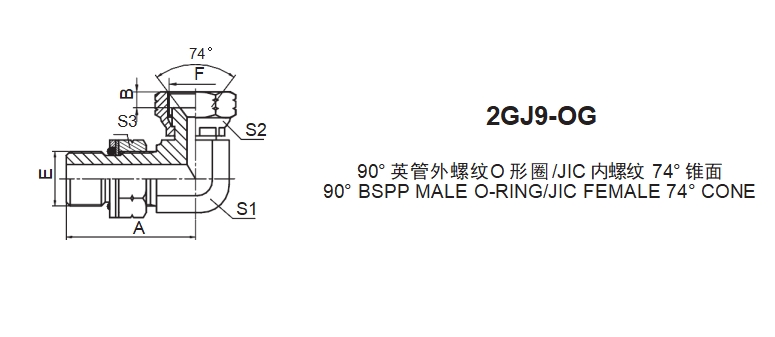

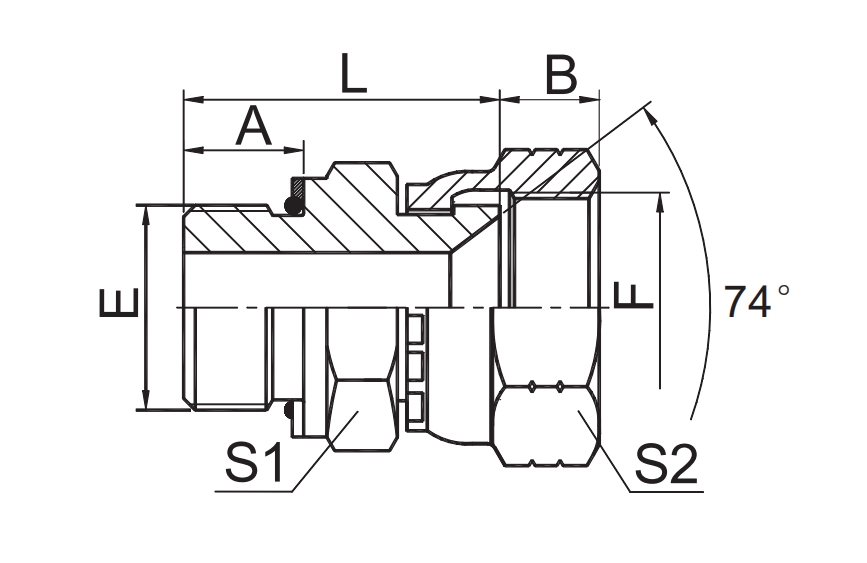

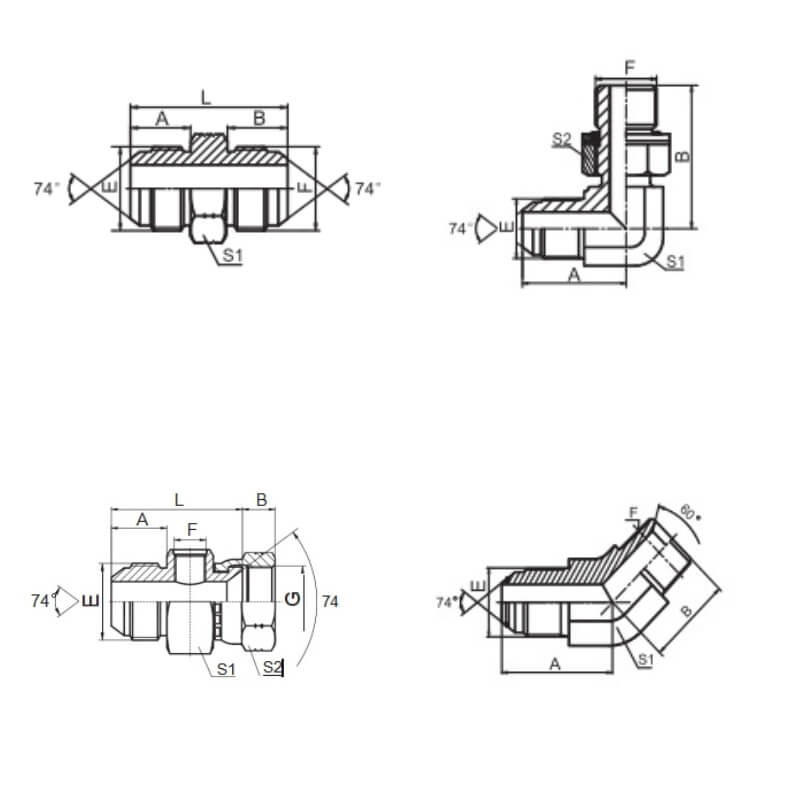

- Versatile Configurations – Straight, elbow, tee, and cross styles to fit various hydraulic layouts.

- High Pressure Capability – Suitable for medium- and high-pressure hydraulic applications.

- Vibration Resistance – Maintains seal integrity in high-vibration environments.

- Corrosion-Resistant Coatings – Zinc plating or special finishes extend service life.

- Multiple Material Options – Available in carbon steel, stainless steel, and brass for different applications.

- Easy Installation and Maintenance – Requires no special tools for assembly or disassembly.

- Broad Industry Application – Ideal for agriculture, construction, marine, aerospace, oil & gas, and industrial equipment.

Applications of JIC Adapters

1. Hydraulic Systems in Construction Equipment

JIC adapters are a standard choice in excavators, bulldozers, loaders, and other heavy machinery. They ensure high-pressure hydraulic lines remain stable during continuous vibration and heavy-duty operation, reducing downtime and maintenance costs.

2. Agricultural Machinery and Implements

From tractors to harvesters, JIC fittings connect hydraulic hoses and tubing that control implements, lifting systems, and steering mechanisms. Their durability makes them suitable for dusty, muddy, and outdoor farming environments.

3. Industrial Manufacturing and Automation

In factories, JIC adapters link hydraulic cylinders, pumps, and control valves in automation lines, presses, and assembly equipment. Their easy installation and precise fit help maintain consistent production speeds.

4. Oil & Gas Exploration and Drilling

High-pressure fluid transfer is critical in drilling rigs, offshore platforms, and refinery operations. JIC adapters offer corrosion resistance and robust sealing, ensuring safe operation in extreme conditions.

5. Marine and Offshore Equipment

Ships, barges, and offshore service vessels use JIC adapters for hydraulic steering, lifting gear, and winch systems, where resistance to saltwater corrosion is essential.

Why Choose JIC Adapters for Your Application?

The versatility of JIC adapters makes them compatible with a wide range of hydraulic hoses and metal tubing. They deliver dependable sealing, resist vibration loosening, and are available in multiple materials such as carbon steel, stainless steel, and brass to match environmental needs.

Customize JIC Adapters for Your Project

When a project demands leak-free, vibration-resistant hydraulic connections, customized JIC adapters (37° flare) let engineers match fit, material, and pressure rating to the exact application — from mobile construction equipment to factory automation.

What can be customized

- Material — carbon steel, 316/304 stainless steel, or brass for seawater, corrosive, or general-purpose use.

- Thread & End Types — straight, 45°/90° elbow, male/female JIC, NPT, BSP, ORFS or custom male/female combinations for mixed-standard systems.

- Size & Tube/O.D. — full range of dash sizes and tube outside diameters to match hoses and tubing.

- Pressure Rating — forged or machined options to meet low-, medium-, and high-pressure hydraulic systems.

- Surface Finish & Coating — zinc plating, passivation, or special coatings for corrosion resistance and extended service life.

- Sealing Options — metal-to-metal 37° flare, bonded-seal, O-ring face or soft-seal variations where required.

- Tolerances & Precision Machining — tighter tolerances for aerospace, transportation, or OEM assemblies.

- Custom Marking & Packaging — laser engraving, part-numbering, and OEM packaging for traceability and assembly-line use.

- Kitting & Assembly — assembled adapter kits, pre-tested hose assemblies, and matched component bundles for faster installation.

Quality assurance & testing

Specify required inspections up front: dimensional inspection reports, material certificates (e.g., 316/304 stainless), torque/pressure testing, and batch traceability. For critical projects, request sample builds and hydrostatic/pressure testing documentation before full production.

How do I order JIC adapters?

- How to order / what to ask for (copyable checklist)

- Provide exact thread types, sizes, and end configurations (example: 7/16-20 JIC male x 1/2" JIC female elbow).

- Specify material (e.g., 316 SS) and surface finish (zinc plated / passivated).

- State working pressure and any temperature/chemical exposure.

- Request certificates: material certs, inspection reports, and sample test records.

- Ask about lead time, MOQ, and available kitting/assembly services.

- For OEM: request branding/laser marking and packaging options.

Leading JIC Adapter Manufacturer in China

Yuyao Jiayuan Hydraulic Fitting Factory, established in 1998, is a leading manufacturer of hydraulic fittings and accessories for construction and agricultural machinery. We are ISO 9001 and IATF 16949 certified, ensuring top-notch product quality. With advanced equipment and a dedicated team, we serve global markets, including Japan, Germany, and the USA, providing value and innovation to our customers.

Why Choose Our JIC Adapters?

Our JIC Adapters are designed to provide robust and reliable connections, ensuring your hydraulic system performs at its best. With high-quality materials and precision engineering, our JIC adapters deliver superior strength, resistance to corrosion, and leak-free sealing, even in the harshest environments.

- High-Pressure Performance: JIC adapters are designed to handle high-pressure systems, providing a reliable, leak-free connection.

- Durability: Made from high-strength materials like stainless steel and carbon steel, our JIC adapters are built to last and resist wear and tear in demanding applications.

- Compatibility: Our adapters conform to industry standards, ensuring compatibility with a wide range of hydraulic hoses, pipes, and fittings.

Not sure which JIC adapter is right for your system? Our experienced team is here to guide you through the selection process. We can help you find the perfect adapter that ensures the efficiency, safety, and performance of your hydraulic system.

FAQs

Q: What is the difference between JIC and NPT fittings?

A: JIC uses a 37° metal flare for a metal-to-metal seal; NPT is tapered pipe thread that seals by thread interference and tape/sealant. They are not directly compatible without an adapter.

Q: What pressure can JIC adapters handle?

A: Pressure depends on size, material and wall thickness; many steel JIC fittings are rated for 3000–6000 psi. Always confirm the adapter's published pressure rating for the specific size/material.

Q: How to measure JIC fittings?

A: To measure JIC fittings, identify the thread size by measuring the outside diameter of the male threads (or inside diameter of the female) and use a thread pitch gauge to determine the threads per inch. Finally, verify the 37° flare angle to distinguish it from other fitting types like SAE 45° or ORFS.

Q: Why should I trust Jiayuan JIC fittings for critical high-pressure systems?

A: Our commitment to zero-leak performance is backed by three technical pillars:

Precision Sealing: Every 37° flare seat is CNC-machined to strict SAE J514 standards, ensuring a perfect metal-to-metal seal that remains leak-free under extreme vibration and pressure surges.

Thread & Tolerance Control: We use GO/NO-GO gauge testing on every batch. This guarantees smooth, burr-free threads and precise dimensional tolerances for consistent torque and easy installation.

Certified Material Integrity: We utilize 100% traceable high-grade steel compliant with IATF 16949. Our fittings feature advanced surface treatments providing over 720 hours of salt spray resistance for maximum service life in harsh environments.

Q: What is the typical lead time for JIC fitting orders?

A: For standard SAE sizes, we maintain a large inventory ready for dispatch within 7–14 days. For large-scale or custom OEM requirements, we leverage our 14,000-square-meter facility and over 140 advanced CNC machines to ensure high-volume output, generally fulfilling specialized orders within 30 to 60 days while providing transparent scheduling for your supply chain.